Manufacturing Case Study

Client Profile

Solutions

- Centerline

- Training & Development

- Root Cause Analysis

- CIL (Clean, Inspect, Lubrication)

- Shop Floor Situational Coaching

- Visual Management

- Speed Accumulation Lost Time (SALT)

Challenge

- Operators not experienced and have very little interaction with their assets

- Site/Lines suffer from a high level of downtime/short stops

- Each shift has their preferred machine settings and way to “run”

- Past experience leads to unnecessary tinkering

- Changeovers are completed with little documentation

- Attempting to identify out-of-set-point settings leads to lengthy troubleshooting

- There is no way to return the machine to “baseline” because the “baseline” isn’t documented

- Material vendors blame material issues on poorly maintained equipment

- Operators rely heavily on Maintenance for equipment setup and adjustment

Approach

- Deep-cleaned the top sources of loss, using heat maps to identify critical focus areas

- CIL standards built to maintain deep clean

- Conducted operator & technical baselines

- Prioritized work orders

Centerline – Find the settings

- Developed a master list of adjustment points

- Facilitated a red dot exercise to eliminate points that should not be adjusted

- Identified changeover and run-right settings for critical adjustment points

- Validated settings across multiple changeovers and runs of each size

Sustain – Maintain the system

- Visual boards installed with CIL checklists and run-right setting audit sheets

- Change control process coached

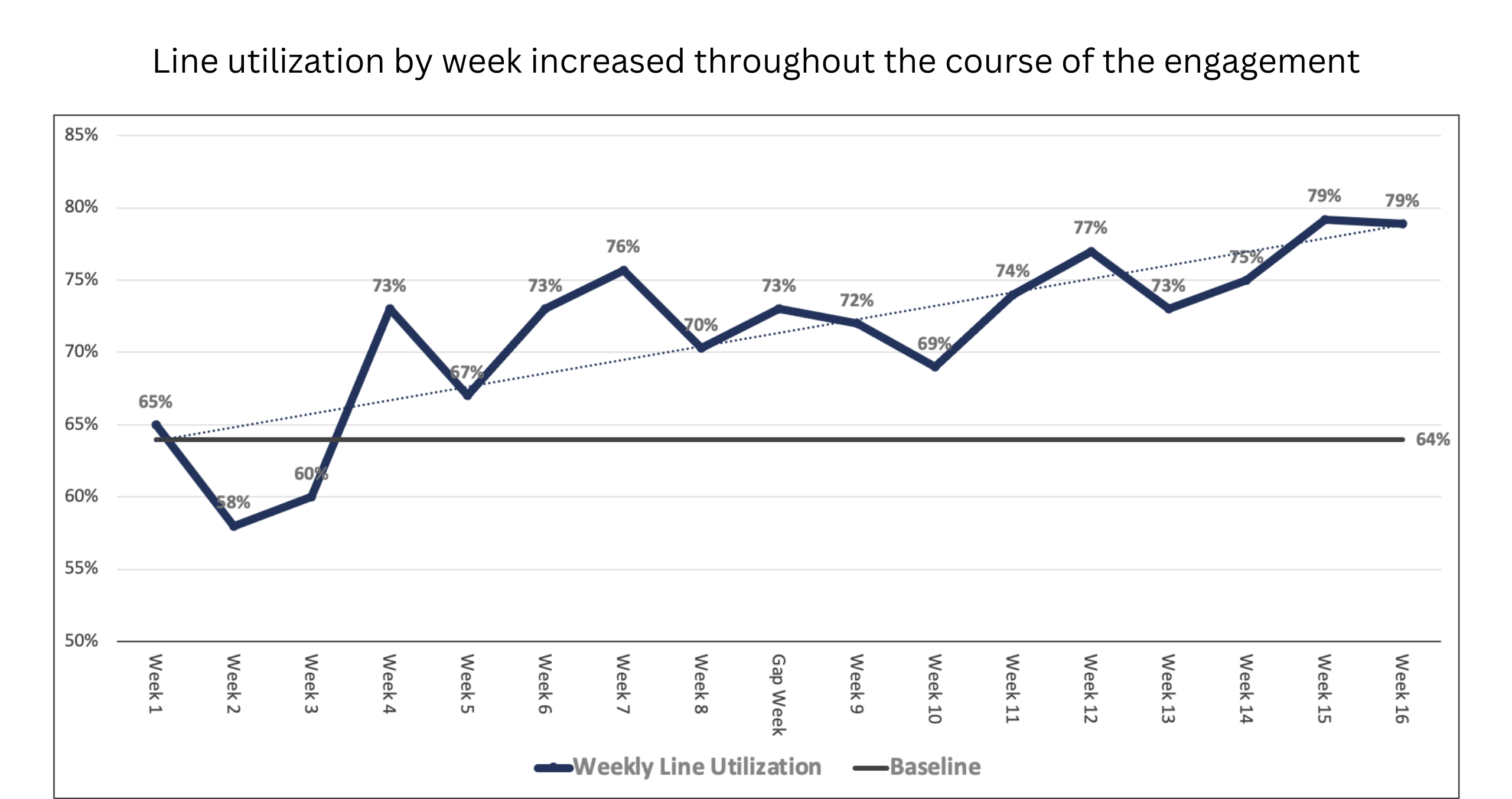

Results

- Provided operational stability by eliminating variation due to “tinkering” with any process

- All operators trained on one right way – everyone runs the process at best performance settings

- Provides a “home base” for changeovers and for troubleshooting issues during production runs

- Raw material issues identified and escalated through consistent machine setting

- Improved effectiveness of operator training and allowed for additional changeover and troubleshooting tasks to be shifted from maintenance to operations

- Line utilization improved by 19% over baseline