Manufacturing Case Study

Client Profile

Solutions

- Key Performance Indicator (KPI) identification

- Meeting structure and effective meetings

- Daily Direction Setting (DDS) meeting

- Shift start-up huddle

- Supervisor handoff

- Top source of loss meeting

- Production scorecard and performance reporting

- Standard Operating Procedures (SOP) and One Point Lessons (OPL)

- Downtime and Yield Loss Escalation Process

- Leader Standard Work (LSW)

- Comprehensive training program

- Visual management

Challenge

Poor Performance and High Waste:

First pass quality (yield) baseline was 75% with no option to rework (any product defects were scrapped), Client also struggled with high raw material waste – baseline average of 13% (with individual shifts over 30% waste). Because of poor performance, client was working overtime to meet current demand, with anticipated future volumes being even higher.

Lack of Alignment from Top Down:

There was a lack of alignment between plant directors, managers, and supervisors on production targets and business objectives. Departments did not have clearly defined KPIs and did not know if performance was good or bad (no targets).

Internal Communication Gaps:

Departments were siloed, with little communication between them. Information was not being effectively communicated or flowing up and down, leading to confusion and contradicting agendas.

Ineffective Meeting Structure:

There was a lack of consistent or effective meetings. When meetings did occur, the focus was on “reporting the news”, not discussing gaps or implementing interim & long-term solutions to prevent recurrence.

Staffing Challenges / Inexperienced Staff:

“Revolving door” of new staff and a lack of depth in training process posed a challenge on how to onboard new employees quickly and effectively to be able to run the line.

Inconsistencies Across Shifts:

There were significant differences in operations & performance between shifts and production lines, despite being identical lines.

Approach

Align on KPIs:

Identify and agree to critical KPIs, track target vs actual at appropriate intervals (hourly, shiftly, daily, weekly).

Design and Install MOS:

Implement standard meetings and tools (action log, dashboard, etc.). Drive problem solving activities with focus on top sources of loss, reviewed weekly. Ensure team is having the right conversations at the right time with the right information to make the right decisions.

Visual Management:

Utilize hour-by-hour boards on the production lines to closely track performance and make timely decisions. Install shift huddle board with most relevant KPIs offering shiftly through weekly recap of performance to inform, motivate, and reward team.

Standards:

Agree to quality and production standards, write SOPs, create OPLs in multiple languages and post in critical positions on the line.

Escalation Processes:

Develop escalation processes for downtime events and for yield losses with set triggers for poor quality and low yield (example: troubleshooting steps and when to contact supervisor for additional support when dealing with bad quality raw materials).

Leader Standard Work:

Create a cadence for supervisors and line leads to ensure consistency across shifts and reduce variance.

Training:

Design a comprehensive training program with up-to-date standards, focusing on all elements of job task (best practice, ergonomic considerations, quality identifiers, escalation triggers, etc.)

Results

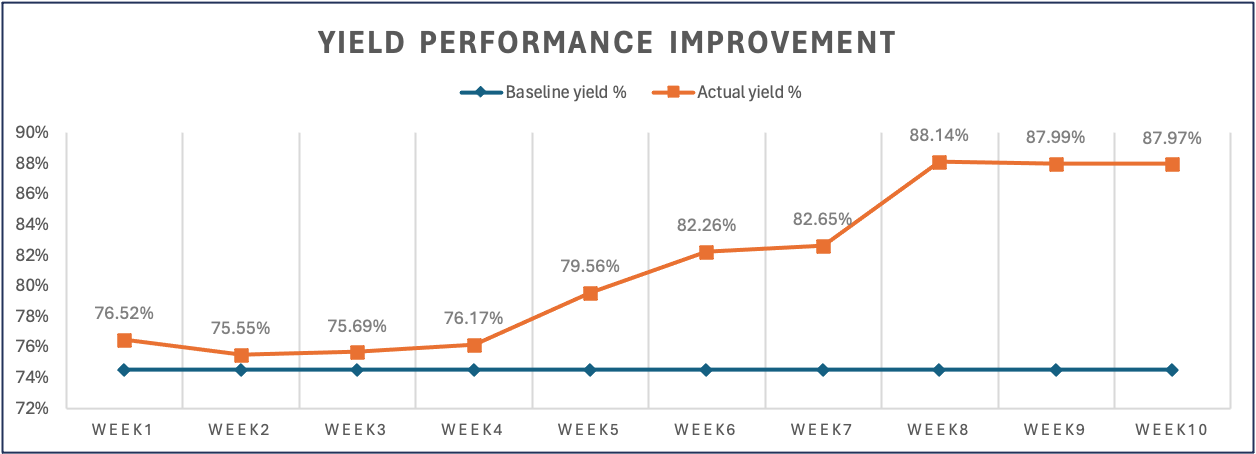

Increased First Pass Quality:

Baseline of 75% increased to 88% (rolling 3-week average)

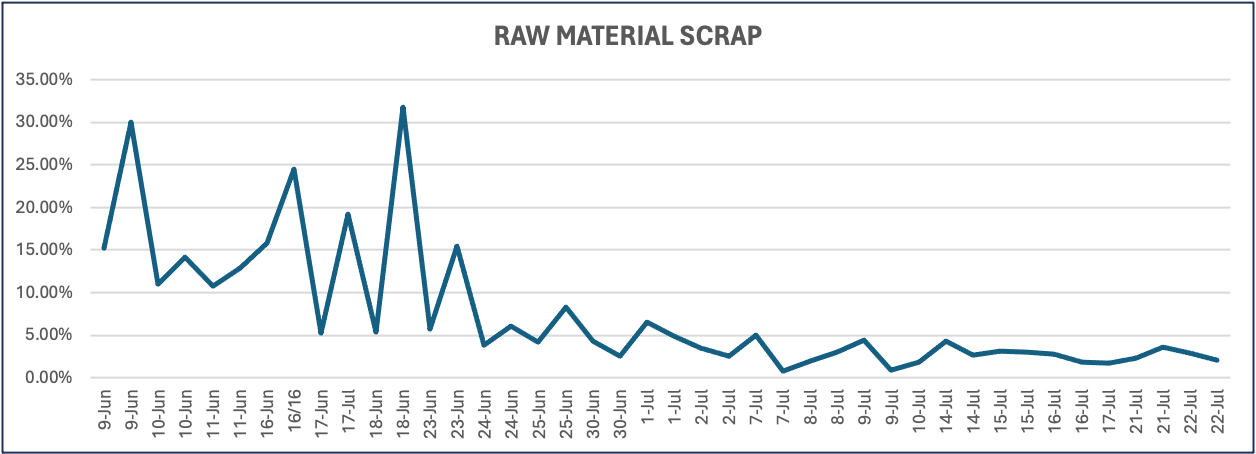

Decreased Raw Material Scrap:

Decreased from upwards of 30% to average of 2.67% (rolling 3-week average)

Clarity in Business Goals and Communication:

Client agreed on KPIs and is now tracking target vs actual and having daily meetings to challenge below target metrics. Departments are collaborating and no longer siloed, and goals are aligned.

Effective Meeting Structure:

Management level meeting, like DDS and top source of loss review, are being used to drive actions to improve performance. Shop floor level meetings, like shift huddle and supervisor handoff, are being used to set clear expectations and ensure consistency across shifts.

Leader Standard Work:

LSW helps supervisors stay on track throughout their day, decreases “fire-fighting”, and is a useful training tool for new supervisors. Standard work for line leads gives a structured cadence and empowers leads to take more responsibility on the line.

Escalation Processes:

Employees are using the downtime and yield loss escalation processes to get issues addressed faster instead of spending hours, shifts, or days fighting problems.

Validated Throughput Targets:

Demonstrated that established run rates, equipment, and training is sufficient to meet budgetary throughput numbers, assuming line is fully staffed, and raw materials are in spec.