Manufacturing Case Study

Client Profile

Solutions

- Consultants partnered with supervisors, working side by side. Consultants provided 24/7 coverage on site, shadowing supervisor the entire time.

- Focus was centered on floor, operator performance-based interaction, confrontation skills, and accountability.

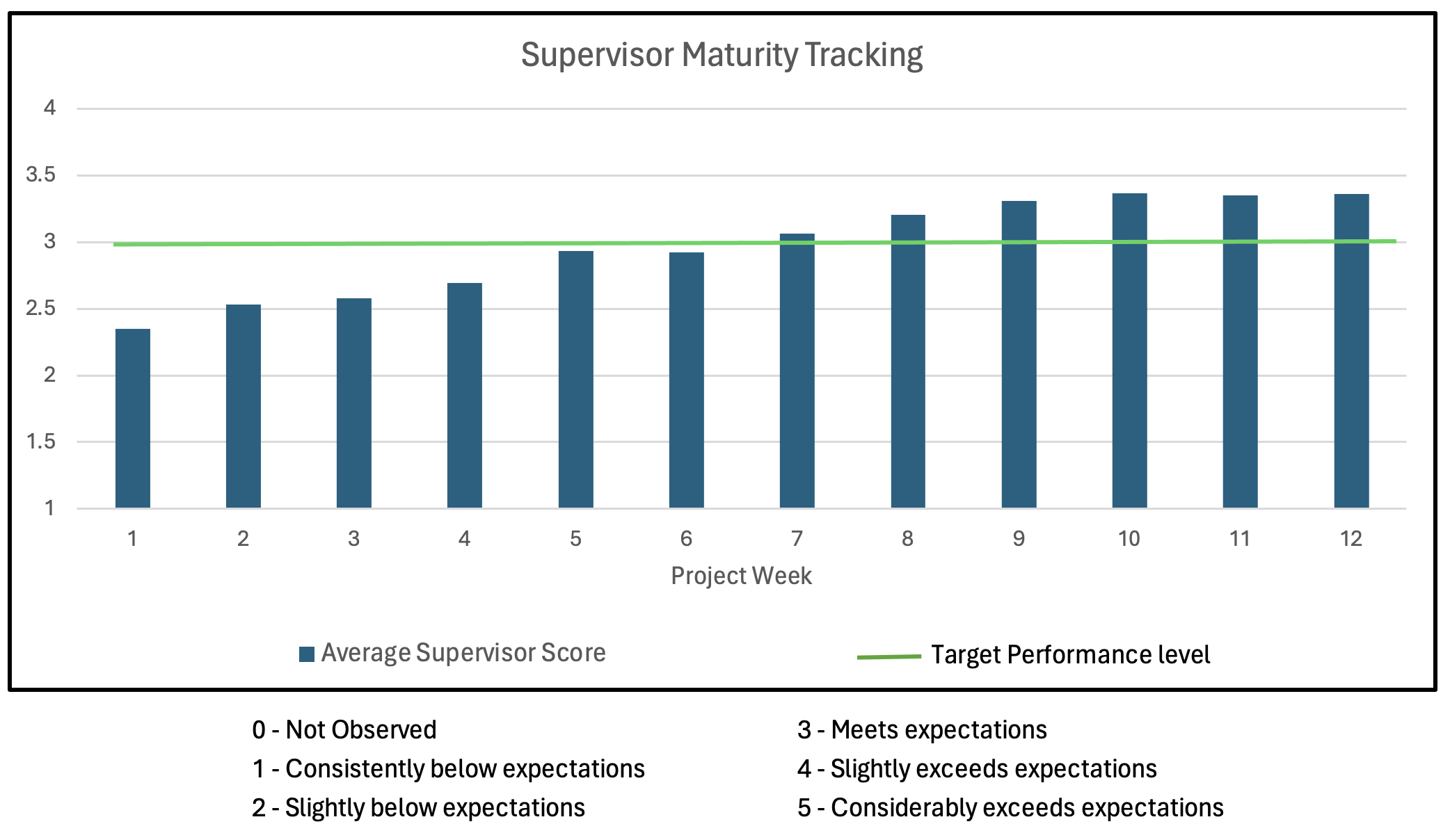

- Supervisors were evaluated daily and graded on 29 elements. One-on-one reviews were conducted on a weekly basis to discuss highlighted opportunities and improvement.

Challenge

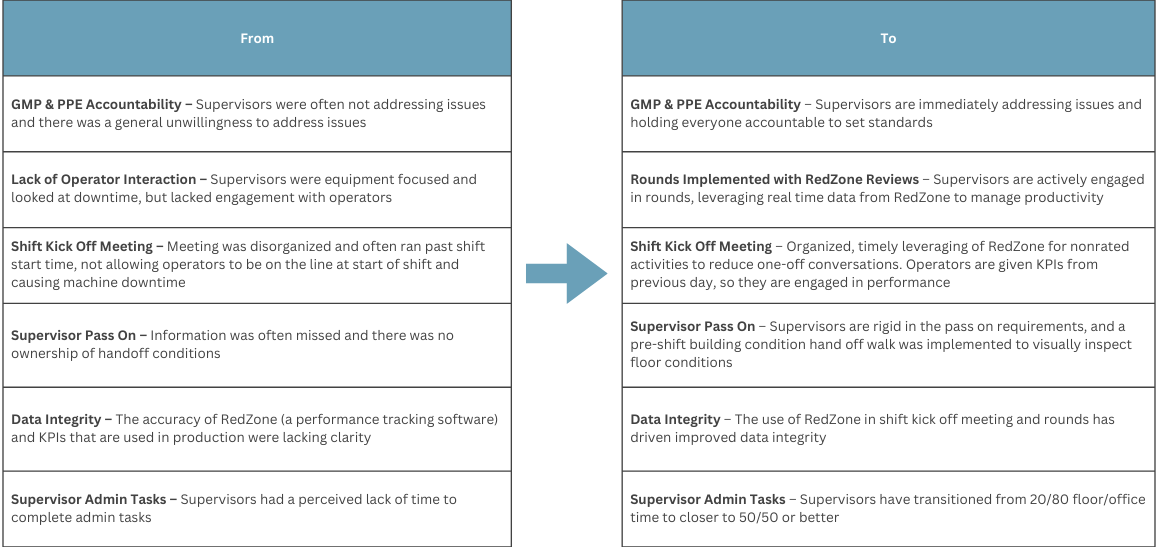

Supervisory Shift Transition

- Supervisors often inherited a plant with poor housekeeping with expected work not completed

- Transfer of information between shifts was spotty, often resulting in substantial lost supervisory and production time because of not knowing current conditions

Shift Change

- Machine downtime at shift change was extensive

- Protracted start up / scheduling meetings prevented operators from getting out on the floor by the start of the shift

- Operators would frequently leave their stations up to 20 minutes before the end of the shift

Unclear Supervisory Roles

- With 2 supervisors per shift, task delineation was unclear

- In some cases, one supervisor would play a purely administrative role with little to no time on the floor

Little Effective Interaction with Operators

- Supervisor’s time on the floor was mostly equipment focused

- If there were interactions with operators, discussions were casual, and performance was not discussed

Lack of Accountability

- Blatant violations of PPE and GMP policies were not confronted

- Actions taken by operators that resulted in significant loss of time or product were routinely “explained away” or ignored, not addressed

Approach

Standardize Transition Process

- Design and install Standardized Pass Down process with agenda

- Implement structured building walks with oncoming supervisor “accepting” current building conditions

Improve Startup Meetings

- Pre-post job assignments, so operators do not have option to choose jobs during meeting to shorten start-up meeting

- Ensure incoming operators relieve outgoing operators at their workstation

Leader Standard Work

- Clearly define and agree to what a typical day in the life of a supervisor should look like including floor tours, process checks, and meetings

- Require supervisory presence on floor to assure operators remain at their stations and with machines running

Performance Based Supervisor Floor Tours

- Formalize floor tours to include online checklists for supervisory review of operating condition and entry of settings and parameters

- Incorporate reviewing current/shift performance with operators as well as validation of downtime reporting, Quality and Metal Detection tests

On Floor Coaching

- Coach supervisors by working side by side with a supervisor

- Focus on discussing situational responses and assuring accountability is administered where warranted

Results

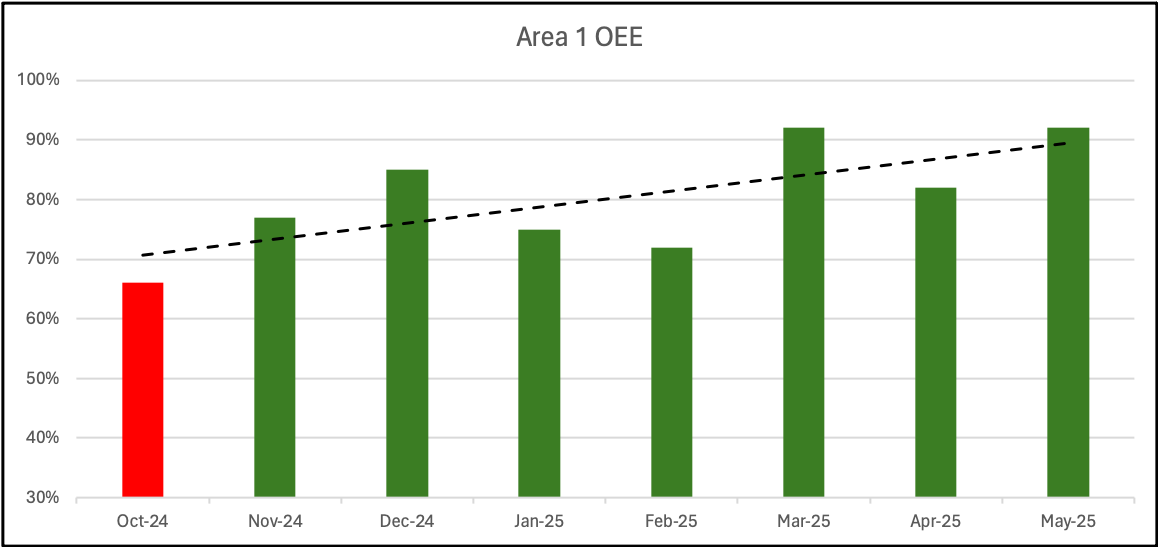

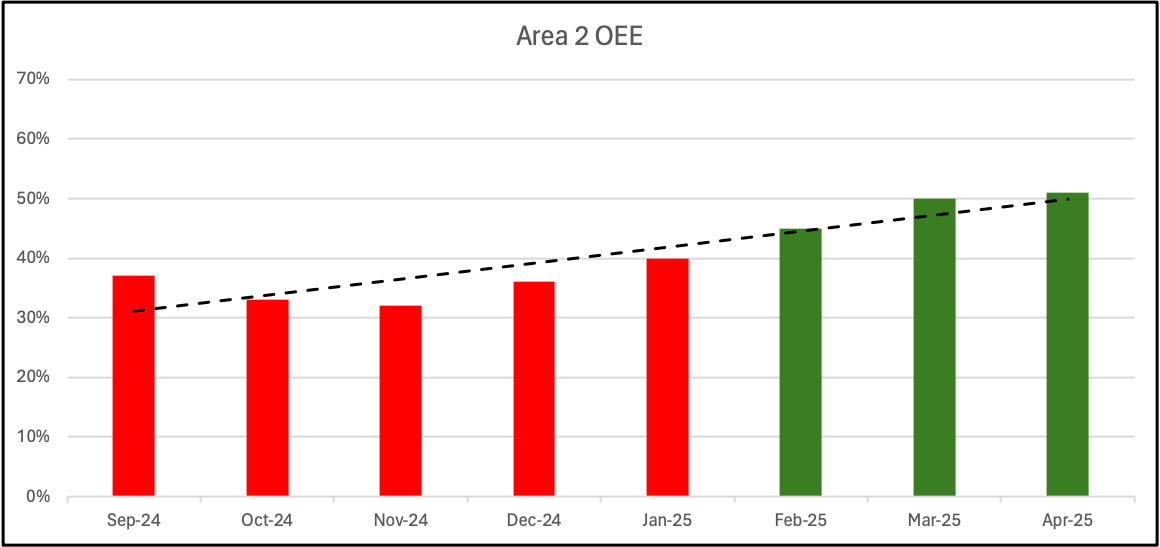

Improved OEE

- OEE increased from 52% to 63%

Regimented Shift Transition Process

- Housekeeping standards have dramatically improved

- Supervisors come in prepared and are no longer “surprised” by conditions on the floor

Effective, Efficient Shift Change

- Lost time at shift change has been virtually eliminated

- Machines continue running through shift change with operators present

Clear Understanding of Roles

- All supervisors balance administrative vs floor time much better. No supervisors are exclusively focused on administrative tasks anymore.

- Supervisors are averaging about 70% of time on the floor

- Daily supervisor routines are much more coordinated and habitual

Constructive Supervisor and Operator interactions

- Discussions with operators are collaborative and occur frequently throughout the shift/day

- The focus is on performance and removing barriers to get back on track

Consistent Application of Accountability and Discipline

- Preliminary discussions and agreement with union allowed a significant increase in accountability

- When appropriate, disciplinary actions were taken, without an increase in grievances

”Performance improvements directly translated into over $1MM in annualized cost savings.